Introduction

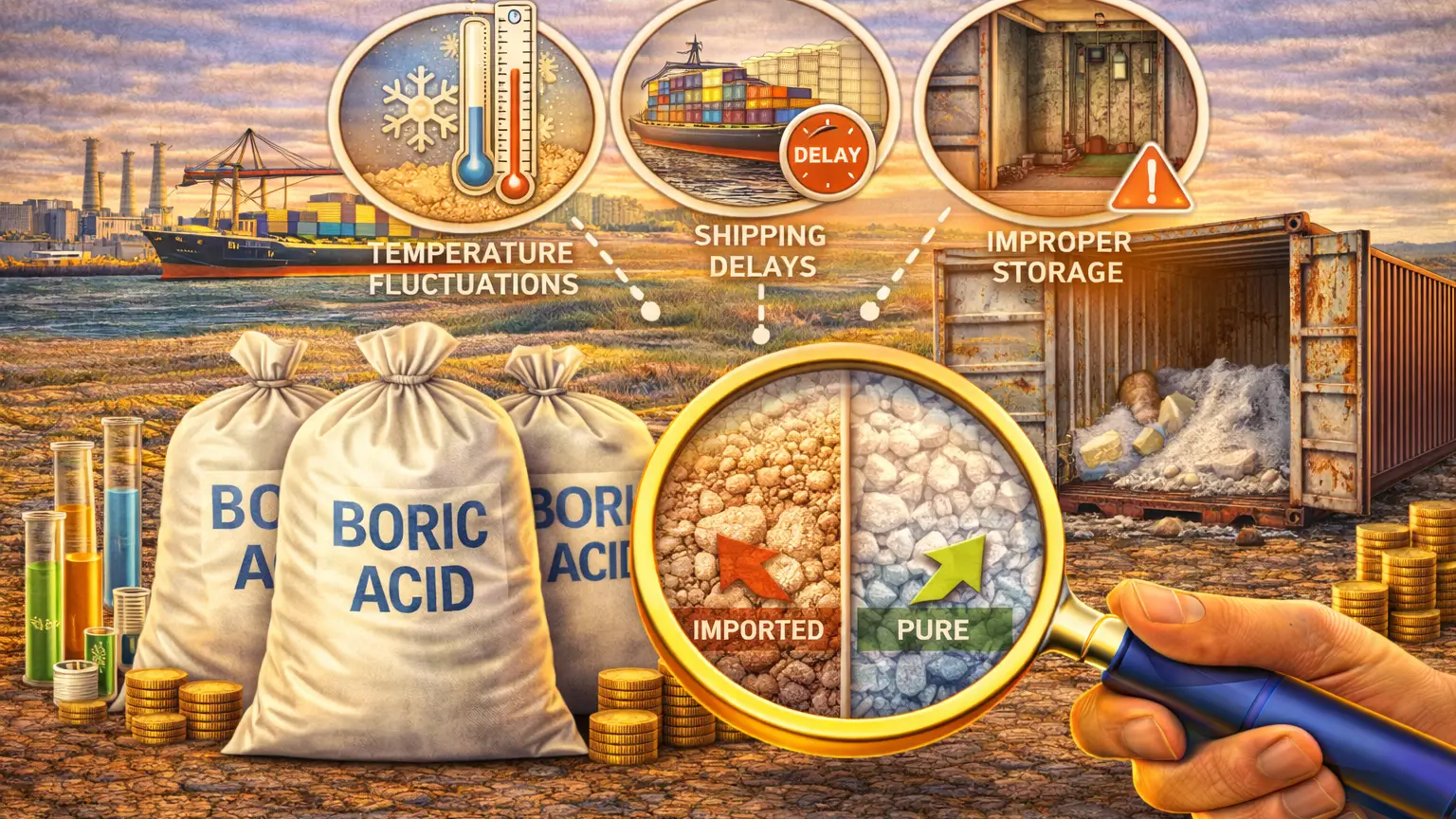

In the vast and intricate supply chains of American industry, the journey of a chemical from manufacturer to end-user is fraught with potential pitfalls. For a versatile and widely used industrial compound like boric acid, its final quality and performance are not solely determined at the point of production. Instead, they are profoundly influenced by the often-overlooked variables of freight and storage conditions. From the humidity in a shipping container crossing the Pacific to the temperature fluctuations in a Midwest warehouse, every environmental exposure can alter the physical and chemical properties of this essential material.

For procurement managers, plant operators, and quality assurance professionals across sectors like agriculture, ceramics, glass manufacturing, and wood treatment, receiving boric acid that meets exact specifications is non-negotiable. Substandard material can lead to production delays, defective end-products, and significant financial loss. This article delves into the science and logistics behind preserving boric acid quality, examining how transportation and warehousing act as the final, critical steps in the quality assurance chain. We will also explore how partnering with a knowledgeable supplier who masters these logistics, such as Chemtradeasia.com, is paramount for securing a consistent, high-performance product.

The Critical Link Between Logistics and Chemical Integrity

Boric acid (H₃BO₃) is prized for its stability, low toxicity, and multifunctional properties as a flame retardant, insecticide, neutron absorber, and precursor to other boron compounds. However, its chemical stability is relative and can be compromised by specific environmental factors. The primary threats during transit and storage are moisture absorption and contamination. Boric acid is mildly hygroscopic, meaning it can attract and hold water molecules from the surrounding atmosphere. This absorption can lead to caking, clumping, and a reduction in effective concentration, which directly impacts dosing accuracy in sensitive applications like glass batch formulation or fertilizer production.

Beyond moisture, physical contamination from dust, debris, or other chemicals during handling, or chemical degradation from exposure to incompatible substances, can render a batch unusable. The logistics phase—encompassing international freight, domestic trucking, and intermediate storage—represents the longest period where the product is outside controlled factory conditions. Therefore, a robust logistics protocol is not an add-on but an integral component of the product specification itself. Understanding this link is the first step in safeguarding your chemical investments and ensuring process reliability.

How Freight Conditions Impact Boric Acid Quality

The freight journey, particularly for imports entering the American market from major producers in Asia or South America, involves multiple modes of transport and handoffs. Each transition point is a potential vulnerability. Ocean freight, the most common method for bulk boric acid, presents unique challenges. Shipping containers, while weatherproof, are not hermetically sealed against humidity. Fluctuating temperatures between day and night can cause "container rain," where moisture condenses on the container ceiling and drips onto cargo. For bagged boric acid, this can lead to soaked and compromised bags, initiating the caking process and promoting mold growth on packaging.

Furthermore, improper stowage aboard vessels, where chemical containers are placed near heat sources or incompatible goods, can accelerate degradation. During overland transport via rail or truck, vibration and shock can damage packaging, leading to tears in bags or ruptures in bulk liners, which then allows for contamination and product loss. A supplier's expertise in selecting appropriate packaging—such as moisture-resistant laminated bags, properly sealed drums, or certified food-grade bulk bags for specific applications—and their partnerships with freight forwarders who understand chemical handling are critical in mitigating these risks from origin to destination port and beyond.

Optimal Storage Conditions for Boric Acid

Once delivered, the responsibility for maintaining boric acid quality shifts to the end-user's storage facilities. Ideal storage conditions are cool, dry, and well-ventilated. The recommended ambient temperature is stable and below 25°C (77°F), with relative humidity consistently below 50%. Warehouses or silos should be devoid of water leaks, significant temperature swings, and exposure to direct sunlight, which can create microclimates of heat and moisture within stacks of bags or drums.

Proper stock rotation using the FIFO (First-In, First-Out) principle is essential to prevent older stock from degrading over extended periods. Bags should be stored on pallets and kept away from walls to allow for air circulation and to prevent moisture wicking from concrete floors. For bulk storage in silos, ensuring the integrity of the silo lining and the effectiveness of desiccant breathers on vents is crucial to prevent atmospheric moisture ingress. Clearly labeling storage areas and segregating boric acid from incompatible materials like strong alkalis or foodstuffs (unless it is a food-grade variant) prevents cross-contamination, preserving both the chemical's purity and workplace safety.

Partnering with a Reliable Supplier: The Chemtradeasia Advantage

Navigating the complexities of international chemical logistics requires a partner with deep expertise and a proactive quality culture. This is where a specialized supplier like Chemtradeasia.com provides significant value beyond mere transaction. As a global supplier serving the American market, Chemtradeasia integrates quality control throughout the entire supply chain. Their process begins with sourcing from reputable manufacturers and continues with stringent pre-shipment inspections to verify product specification, packaging integrity, and container suitability.

Chemtradeasia offers boric acid in various forms tailored to different industry needs, including Technical Grade, USP/NF Grade (for pharmaceutical and food applications), and Agricultural Grade. Each grade has specific packaging protocols. For instance, their USP-grade boric acid is typically supplied in double-lined, food-grade polyethylene bags to ensure utmost purity, while technical-grade material for industrial use might come in cost-effective, high-strength moisture-barrier bags. Their logistical network is built with chemical compatibility in mind, ensuring that your shipment is never co-loaded with hazardous or incompatible goods. By providing comprehensive documentation, including Certificates of Analysis (CoA) and Material Safety Data Sheets (MSDS) that trace the product's journey, they offer transparency and assurance that the boric acid quality delivered is the quality that was produced.

Best Practices for Receiving and Handling Boric Acid

The moment of delivery is a critical checkpoint. A thorough receiving inspection can identify issues caused during transit before the product enters your inventory. Visually inspect all bags, drums, or containers for signs of damage, water stains, or compromised seals. Check the packaging for the product grade, lot number, and manufacturer/supplier information to ensure it matches your order. It is advisable to sample and perform quick tests, such as checking for excessive moisture or clumping, especially if the shipment experienced known delays or extreme weather.

Proper handling equipment, like bag dump stations with dust collection systems or enclosed conveyor systems for bulk transfer, minimizes product loss and exposure to ambient humidity. Personnel should be trained in safe handling procedures using appropriate personal protective equipment (PPE). Implementing a documented quality control protocol for incoming chemicals, with clear acceptance/rejection criteria, formalizes this process and creates a record that can be used to address any quality disputes with carriers or suppliers promptly, ensuring accountability and continuous improvement in your supply chain.

Conclusion

The delivered quality of boric acid is a direct reflection of the care taken during its journey from the factory floor to your facility. Freight and storage conditions are not mere logistical details but are active determinants of the chemical's efficacy and value. Moisture, contamination, and improper handling at any stage can degrade a premium product into a substandard one, with real consequences for production outcomes and the bottom line.

Proactive management of these conditions, through informed receiving practices and optimal warehouse management, is essential. However, the foundation of success lies in selecting a supplier who views logistics as an extension of their quality promise. Partners like Chemtradeasia.com, with their product-specific expertise, robust packaging standards, and chemical-aware logistics networks, provide American industries with the reliability needed in today's competitive landscape. By prioritizing the integrity of the entire supply chain, businesses can ensure that the boric acid they specify is the boric acid that delivers, batch after batch.

Leave a Comment