Introduction

The American chemical industry is undergoing a significant shift towards greater transparency and accountability, particularly in the trade of essential industrial compounds like boric acid. Once a transaction driven primarily by price and basic specifications, the boric acid supply chain is now increasingly governed by rigorous quality assurance protocols, with independent third-party testing emerging as a non-negotiable standard. This trend reflects a broader movement across manufacturing sectors, where end-users in agriculture, ceramics, glass, and wood treatment demand guaranteed purity, consistency, and regulatory compliance.

For procurement managers and quality assurance professionals, the stakes have never been higher. Contaminated or sub-specification industrial boric acid can lead to catastrophic production failures, product recalls, and severe regulatory penalties. Consequently, relying solely on a supplier's Certificate of Analysis (CoA) is no longer deemed sufficient. The modern paradigm involves verifying those claims through accredited, unbiased laboratories. This article delves into the drivers behind this trend, explores the specific applications demanding such scrutiny, and outlines how partnering with a conscientious supplier like Chemtradeasia.com, which prioritizes verifiable quality, is becoming a strategic imperative for American businesses.

The Critical Role of Quality in Industrial Boric Acid

Boric acid (H3BO3) is a versatile inorganic compound with a surprisingly wide array of industrial applications. Its efficacy and safety in any given process are directly tied to its chemical purity and physical properties. For instance, in the manufacture of borosilicate glass, which is renowned for its thermal shock resistance, even trace amounts of metallic impurities like iron or sodium can compromise the glass's clarity and structural integrity. In agricultural applications, where boric acid is used as a micronutrient fertilizer, the presence of heavy metals such as lead or arsenic poses serious environmental and health risks, potentially contaminating soil and food chains.

Beyond purity, physical specifications such as particle size distribution (granulation) and moisture content are equally critical. In flame retardancy applications for cellulose insulation or plastics, inconsistent particle size can lead to uneven dispersion, creating weak points in fire resistance. Similarly, high moisture content in boric acid intended for metallurgical fluxes can cause spattering and safety hazards in high-temperature processes. Therefore, quality in industrial boric acid is not a single metric but a comprehensive profile that must be meticulously controlled and, importantly, independently verified to ensure it aligns with the precise needs of the downstream application.

Why Independent Testing is Gaining Traction

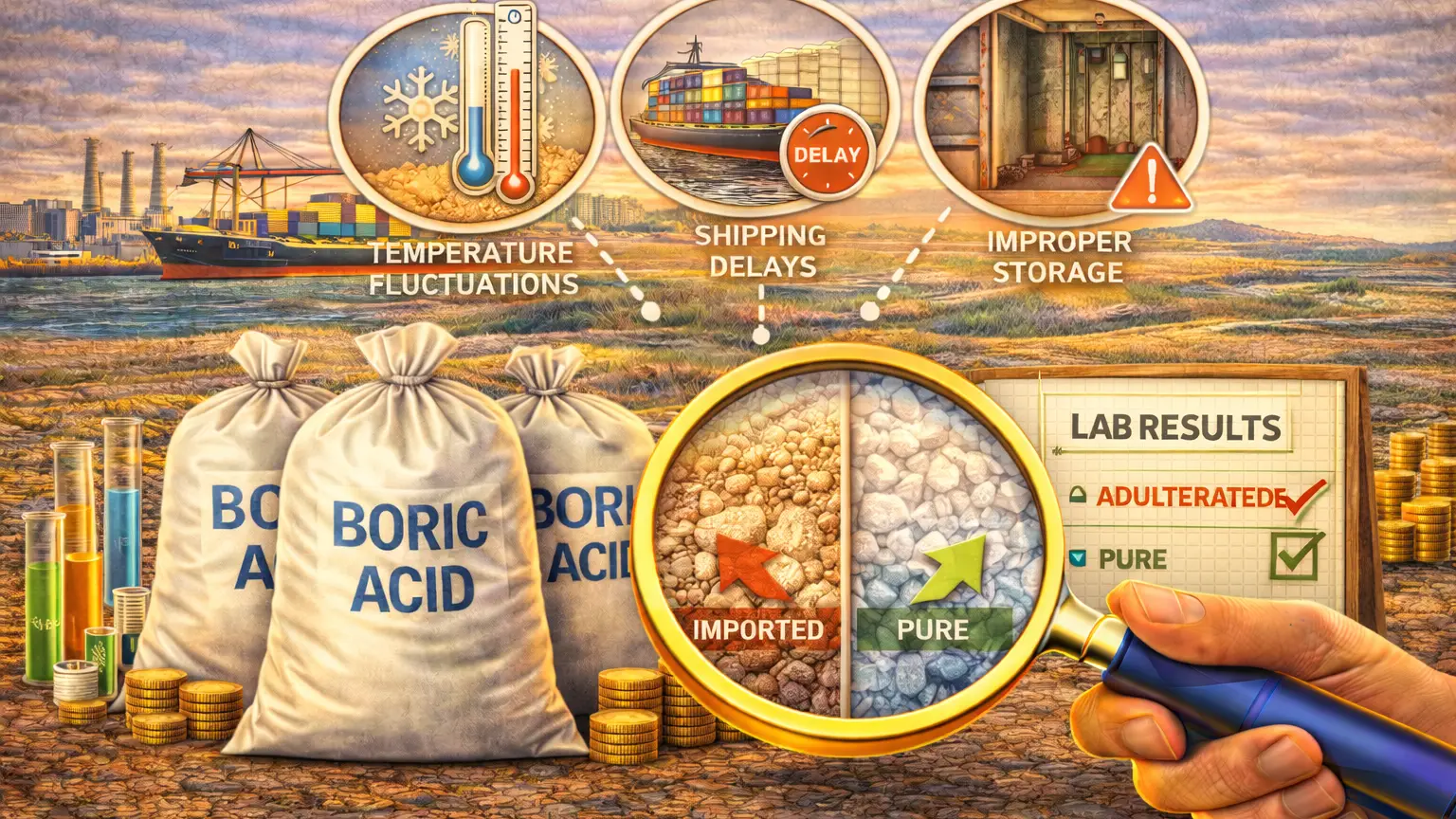

Several converging factors are propelling the adoption of independent testing from a best practice to a common requirement in the American boric acid trade. First is the intensification of regulatory oversight. Agencies like the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) have stringent guidelines for chemicals used in pesticides, food contact materials, and pharmaceuticals. An independent test report from an ISO/IEC 17025 accredited laboratory provides defensible evidence of compliance, shielding both buyer and seller from liability in the event of an audit or product failure.

Second, globalization of supply chains has introduced complexity and risk. Sourcing boric acid from international producers, while cost-effective, can lead to inconsistencies in quality standards and documentation. An independent lab serves as a neutral arbitrator, testing material upon arrival at U.S. ports or warehouses to confirm it matches the purchase order specifications before it enters the production line. This "trust but verify" approach mitigates financial loss and operational downtime. Furthermore, in an era of heightened corporate social responsibility, companies are leveraging independent testing to validate claims about product sustainability and responsible sourcing, which are increasingly important to investors and consumers.

Key Applications and Specifications Driving Demand

The push for independent verification is most pronounced in applications where boric acid performance is mission-critical. In the **glass and ceramics industry**, specifications for optical glass or laboratory ware demand boric acid with a minimum of 99.5% purity, extremely low iron content (often below 50 ppm), and controlled chloride and sulfate levels. Independent testing verifies these ultra-high purity grades, ensuring the final product has the desired refractive index and chemical durability. For **wood preservation and pest control**, efficacy depends on the compound's solubility and consistent concentration. Tests confirm the active ingredient percentage and rule out the presence of ineffective or harmful fillers.

Another major sector is **flame retardants**. Here, boric acid is often blended with other compounds to treat textiles, plastics, and insulation. Independent analysis not only checks purity but also the compound's dehydration behavior, as its flame-retardant action is partially dependent on releasing water vapor when heated. In **nuclear power** applications, boric acid is used as a neutron absorber in coolant water. The required nuclear-grade material has perhaps the most stringent specifications of all, with limits on neutron-absorbing impurities like cadmium and gadolinium that are so low they can only be reliably confirmed by highly specialized, independent laboratories using techniques like ICP-MS (Inductively Coupled Plasma Mass Spectrometry).

The Process and Benefits of Third-Party Verification

The process of independent testing typically begins with a statistically representative sample being drawn from a shipment, following strict chain-of-custody protocols to prevent tampering or contamination. This sample is then sent to an accredited third-party laboratory, unaffiliated with either the buyer or seller. The lab conducts a battery of tests aligned with recognized standards such as ASTM or USP methods. These may include assay/purity by titration, heavy metals analysis, loss on drying (moisture), particle size analysis via sieve or laser diffraction, and specific tests for anions like chloride and sulfate.

The benefits of this rigorous process are manifold. For the buyer, it provides **unbiased quality assurance**, reducing dependency on the supplier's self-reported data and enabling informed purchasing decisions. It **mitigates supply chain risk** by catching non-conforming material early, preventing costly production stoppages, rework, or finished product failures. It also **strengthens supplier relationships** by establishing a clear, objective benchmark for quality, fostering transparency and continuous improvement. For the supplier, such as a reputable partner like Chemtradeasia.com, offering pre-verified shipments or facilitating independent testing builds immense trust and differentiates them in a competitive market, demonstrating a commitment to quality that goes beyond mere claims.

Choosing a Reliable Boric Acid Supplier

In this new landscape, selecting a boric acid supplier requires evaluating more than just price and availability. A reliable partner will have a transparent quality management system and be proactive about verification. Look for suppliers who provide detailed, batch-specific Certificates of Analysis and are willing to have those CoAs validated by a customer-appointed third party. Suppliers who source from ISO-certified manufacturers and have long-term relationships with producers are generally more consistent. A key indicator is a supplier's willingness to provide samples for your own testing before committing to a large order.

Platforms like Chemtradeasia.com exemplify this modern approach to chemical distribution. They act not just as intermediaries but as quality gatekeepers, often conducting or requiring initial testing from their network of producers. They understand the specific grade requirements for different American industries—whether it's technical grade for insecticides, USP grade for cosmetics, or high-purity grade for electronics. By providing comprehensive technical data sheets, facilitating logistics for sample testing, and ensuring clear documentation for customs and regulatory compliance, they reduce the administrative and technical burden on the buyer, making the integration of independent testing a seamless part of the procurement process.

Conclusion

The normalization of independent testing in the American boric acid trade is a definitive sign of market maturation and heightened quality consciousness. It is a proactive response to the complexities of global supply chains, stringent regulatory environments, and the technical demands of advanced manufacturing. This practice transforms quality from a promised attribute into a demonstrable, documented fact, protecting investments and reputations across the supply chain.

Ultimately, this trend elevates the role of the chemical supplier from a simple vendor to a strategic partner in quality assurance. By aligning with suppliers who embrace transparency and verification, such as those who prioritize rigorous standards, American industries can secure a competitive edge through guaranteed material consistency, enhanced product performance, and unparalleled supply chain resilience. In the trade of essential chemicals like boric acid, independent testing is no longer an optional extra; it is the cornerstone of responsible and successful commerce.

Leave a Comment