Introduction

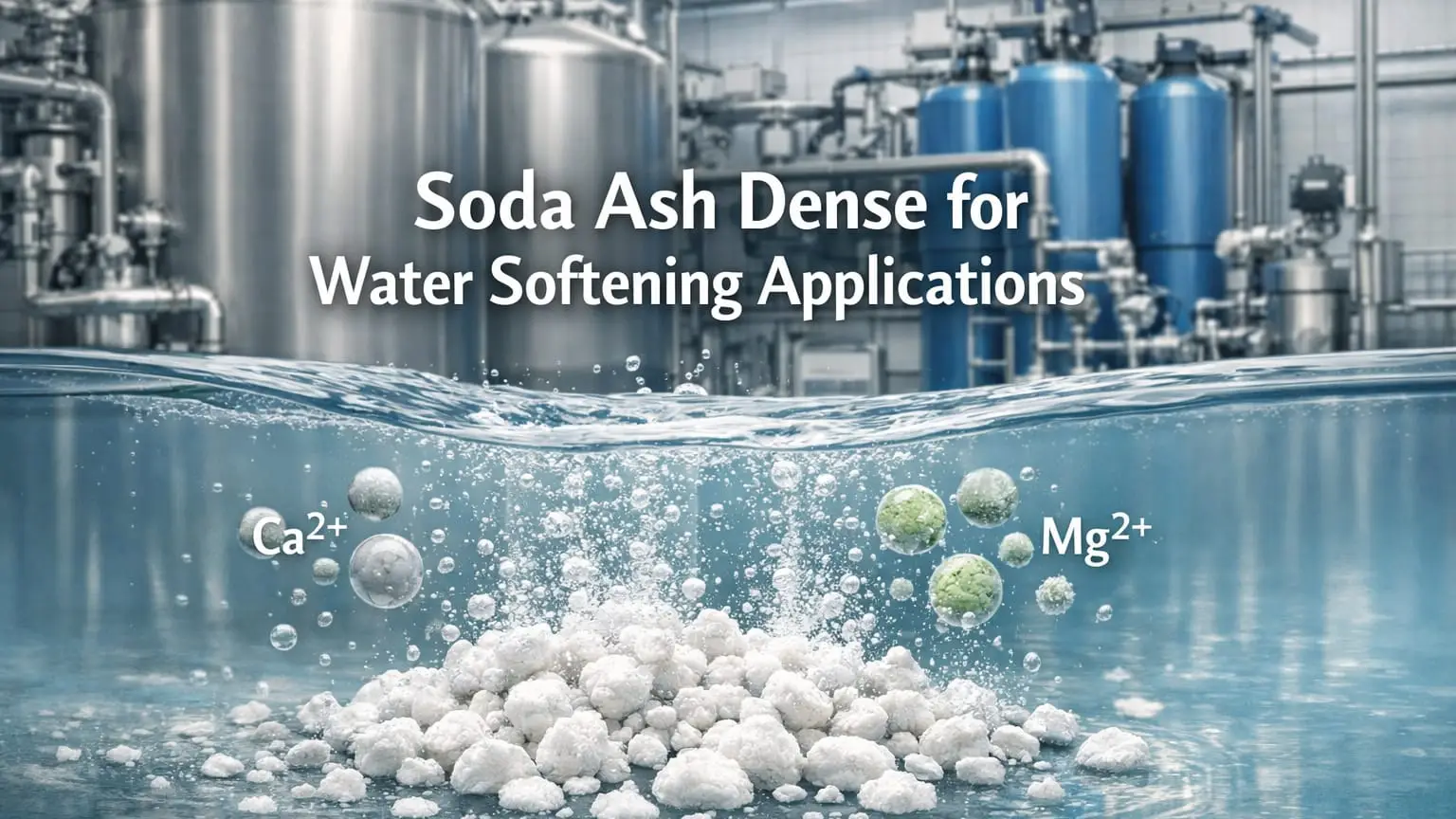

Soda ash dense for water softening plays a critical role in maintaining water quality across industrial and municipal systems. Water hardness, caused by dissolved calcium and magnesium ions, continues to challenge operators worldwide. These minerals form scale inside boilers, heat exchangers, cooling towers, and pipelines, reducing heat transfer efficiency, increasing energy use, and accelerating equipment wear. In municipal networks, hard water also affects distribution infrastructure and reduces end-user satisfaction through visible scaling and poor soap performance.

To manage these challenges effectively, many facilities rely on soda ash dense as a proven and scalable water softening chemical. Dense sodium carbonate supports reliable hardness removal, cost control, and long-term system protection. This article explores how soda ash dense works in water softening, where it is most commonly applied, and why sourcing from trusted suppliers such as Chemtradeasia is essential for consistent treatment performance.

Understanding Water Hardness and Its Impact

Water hardness refers to the concentration of dissolved calcium and magnesium ions, commonly measured in milligrams per liter or parts per million as calcium carbonate equivalent. These ions enter water supplies naturally as groundwater and surface water flow through mineral-rich geological formations such as limestone and dolomite.

Hardness is often divided into temporary hardness, which is associated with bicarbonates and partially reduced by heating, and permanent hardness, which is linked to sulfates and chlorides and requires chemical treatment. Without proper control, hard water creates scale deposits that restrict flow and insulate heat transfer surfaces. Even a thin scale layer can significantly reduce thermal efficiency, leading to higher fuel consumption and increased operating costs.

In large-scale industrial and municipal systems that treat millions of cubic meters of water each year, unmanaged hardness translates directly into higher maintenance expenses, unplanned downtime, and reduced asset lifespan. Effective water softening is therefore a fundamental requirement rather than an optional upgrade.

How Soda Ash Dense Works in Water Softening

Soda ash dense removes hardness through precipitation reactions. Once dissolved in water, sodium carbonate releases carbonate ions that react with dissolved calcium and magnesium. These reactions form insoluble calcium carbonate and magnesium carbonate, which can then be removed through sedimentation and filtration.

Calcium hardness removal occurs when calcium ions combine with carbonate ions to form solid calcium carbonate. Magnesium removal follows a similar pathway but requires higher pH levels, which are often achieved by adding lime alongside soda ash. For this reason, soda ash dense is frequently used in combination with calcium hydroxide in lime soda ash softening systems.

This approach allows operators to remove both carbonate and non-carbonate hardness effectively. Calcium precipitation typically occurs at pH levels between 9.5 and 10.5, while magnesium removal requires pH values above 10.5. Accurate dosing and continuous monitoring are essential to maintain these conditions and achieve consistent hardness reduction.

Key Applications of Soda Ash Dense in Water Softening

Boiler Feedwater Treatment

Boiler systems are highly sensitive to hardness, especially in high-pressure operations. Even small amounts of calcium and magnesium can cause severe scaling and tube failure. Soda ash dense, used alongside lime, supports hardness reduction to very low levels, helping facilities meet strict boiler feedwater standards and protect critical equipment.

Cooling Tower Systems

Cooling towers operate under conditions that promote scale formation due to evaporation and concentration cycles. Pre-softening makeup water with soda ash dense reduces calcium levels, minimizes fouling, and improves heat transfer efficiency. This leads to lower energy consumption and extended system life.

Municipal Drinking Water Treatment

Many large municipal treatment plants use lime soda ash softening to treat hard groundwater or surface water. This method reduces hardness, alkalinity, and turbidity while improving water clarity and distribution system durability. Consumers benefit from improved water quality and reduced scaling in household plumbing.

Reverse Osmosis Pre-treatment

Soda ash dense is increasingly applied upstream of reverse osmosis systems to lower scaling potential on membranes. By reducing calcium concentrations before filtration, facilities can extend membrane life and reduce chemical cleaning frequency.

Advantages of Using Soda Ash Dense for Water Softening

Soda ash dense offers several advantages that make it attractive for large-scale applications. The chemistry of hardness removal is well understood and predictable, allowing precise stoichiometric control. Compared with ion exchange or membrane-based systems, chemical softening using soda ash is often more economical for high-volume treatment.

The dense grade improves handling safety and operational efficiency by reducing dust exposure and supporting both manual and automated dosing. Storage and transportation costs are lower due to reduced volume requirements, and compatibility with lime, coagulants, and flocculants simplifies process integration.

Sourcing Reliable Soda Ash Dense

Consistent product quality is essential for stable water softening performance. Variations in purity, moisture content, or particle size can affect dissolution and dosing accuracy. Working with reputable suppliers ensures reliable specifications and uninterrupted supply.

Chemtradeasia provides access to vetted global manufacturers of soda ash dense, offering transparent technical data, certificates of analysis, and flexible logistics solutions. Partnering with Chemtradeasia helps water treatment operators maintain consistent chemical quality and secure long-term supply reliability.

Conclusion

Soda ash dense for water softening remains a proven and scalable solution for managing hardness in industrial and municipal water systems. Its straightforward precipitation chemistry, compatibility with lime-based processes, and superior handling characteristics make it well suited for high-capacity installations.

When applied correctly and sourced from trusted suppliers, soda ash dense helps prevent scale formation, protect equipment, improve energy efficiency, and maintain stable water quality. As demand for efficient and sustainable water treatment continues to grow, Chemtradeasia stands ready to support operators with reliable soda ash dense solutions tailored to modern water softening needs.

Leave a Comment