Introduction

In the complex and high-stakes world of American industrial procurement, confidence is the ultimate currency. For buyers sourcing essential materials like sodium bicarbonate and other industrial chemicals, the relationship with a supplier transcends a simple transaction. It becomes a strategic partnership underpinned by trust, reliability, and shared values. In an era marked by supply chain volatility and increasing regulatory scrutiny, American manufacturers are scrutinizing their suppliers more closely than ever. They seek partners who do more than just deliver a product; they seek allies who ensure operational continuity, mitigate risk, and contribute to their own brand's integrity.

This article delves into the specific, actionable supplier practices that forge and sustain long-term buyer confidence in the American market. We will explore how leading suppliers, such as Chemtradeasia.com, operationalize trust through transparency, unwavering quality, and logistical excellence. By understanding these pillars, procurement professionals can better evaluate their chemical supply partners and suppliers can align their operations to meet the exacting standards of the world's most demanding industrial landscape.

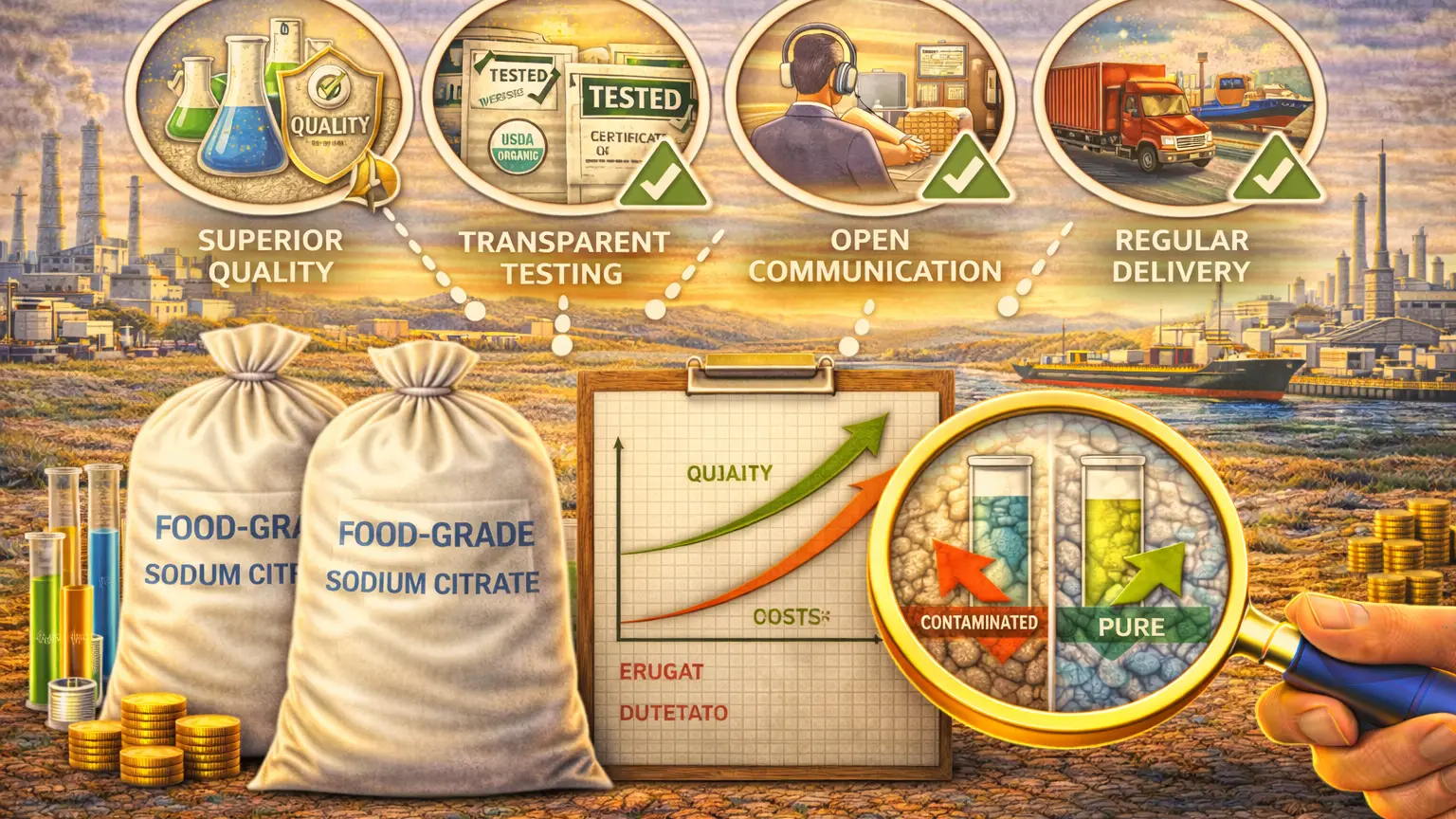

The Pillars of Trust in Chemical Supply

Building lasting confidence with American buyers is not accidental; it is architected on several foundational pillars. The first is consistency. In industries ranging from food processing to pharmaceuticals and environmental remediation, batch-to-batch consistency in chemical products like sodium bicarbonate is non-negotiable. A single deviation can halt a production line, compromise a final product, or lead to costly regulatory non-compliance. Trustworthy suppliers implement rigorous, documented processes to ensure that every shipment meets identical specifications, providing buyers with the peace of mind that their processes will run smoothly.

The second pillar is proactive partnership. A confident supplier acts as an extension of the buyer's team. This involves more than reactive customer service; it includes proactive market intelligence sharing, early notification of potential price or supply fluctuations, and collaborative problem-solving. For instance, a supplier aware of a potential port congestion issue will communicate alternative shipping solutions well in advance, rather than waiting for a delay to occur. This forward-looking approach transforms the supplier from a vendor into a valued consultant, deeply invested in the buyer's success.

Finally, ethical and sustainable sourcing has become a critical trust factor. American corporations are increasingly accountable to stakeholders for their supply chain's environmental and social impact. Suppliers who can provide clear documentation on the origin of their raw materials, demonstrate adherence to responsible mining or manufacturing practices, and offer products with a lower carbon footprint directly contribute to the buyer's ESG (Environmental, Social, and Governance) goals. This alignment on values strengthens the business relationship at a fundamental level.

Spotlight on Sodium Bicarbonate: A Versatile Workhorse

Sodium bicarbonate, commonly known as baking soda, is a quintessential example of a chemical whose reliable supply is critical across diverse American industries. Its applications are vast, and each demands specific grades and consistent quality. A supplier's expertise is measured by their ability to navigate this complexity. For the food and beverage industry, food-grade sodium bicarbonate must comply with strict FDA standards and possess the precise alkalinity and granulation for leavening, pH adjustment, or cleaning. Any impurity can alter taste, texture, or safety.

In contrast, industrial and pharmaceutical grades serve vastly different purposes. Industrial-grade bicarbonate is used in flue gas desulfurization to scrub pollutants from power plant emissions, requiring specific particle size and reactivity. Pharmaceutical-grade material, used in dialysis solutions and antacid formulations, demands unparalleled purity, often meeting or exceeding USP (United States Pharmacopeia) standards. A confident supplier like Chemtradeasia.com doesn't just sell a generic powder; they provide the exact specification—be it ACS Reagent Grade, FCC Grade, or Technical Grade—with certified documentation for each batch, ensuring it is fit-for-purpose in the buyer's specific application.

The supplier's role extends to innovation and education. A trusted partner will inform buyers about emerging applications, such as the use of sodium bicarbonate in eco-friendly cleaning products or as a fire suppressant for electrical fires. They provide technical data sheets, safety information, and handling guidelines that empower buyers to use the product safely and effectively. This depth of product knowledge and support turns a commodity transaction into a value-added service, cementing the supplier's position as an indispensable resource.

Transparency and Communication as Core Competencies

In the digital age, opacity is a deal-breaker. American buyers expect radical transparency throughout the supply journey. This begins with clear, upfront pricing that details all costs, avoiding hidden fees that erode trust. It continues with real-time order tracking; knowing a shipment's exact location from origin port to destination warehouse reduces anxiety and allows for better production planning. Suppliers who invest in integrated logistics platforms provide this visibility as a standard service, demonstrating respect for the buyer's time and operational needs.

Communication must be consistent, multi-channel, and culturally attuned. The American business culture values directness, promptness, and solutions-oriented dialogue. A supplier's responsiveness to inquiries, their ability to provide clear answers in English from knowledgeable account managers, and their willingness to schedule calls across U.S. time zones are all tangible indicators of commitment. Furthermore, transparent communication about capacity, lead times, and potential challenges—even when the news is unfavorable—builds more credibility than optimistic promises that cannot be kept.

This transparency also applies to corporate identity and capabilities. Buyers increasingly conduct deep due diligence. A supplier with a professional, informative digital presence, such as a comprehensive website like Chemtradeasia.com, that clearly lists products, certifications, and company information, starts the relationship on solid ground. Showcasing client testimonials, case studies, and detailed quality control processes online pre-emptively answers buyer questions and establishes legitimacy before the first contact is even made.

Quality Assurance and Regulatory Mastery

For American buyers, quality is quantified and documented. Trust is built on a foundation of internationally recognized certifications and auditable processes. A supplier's commitment to quality is demonstrated through certifications like ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and for food-grade products, FSSC 22000 or equivalent food safety standards. These are not mere badges on a website; they represent a systemic, process-driven approach to excellence that minimizes risk for the buyer.

Mastery of the complex American regulatory landscape is non-negotiable. This includes deep understanding of regulations from the FDA (Food and Drug Administration), EPA (Environmental Protection Agency), OSHA (Occupational Safety and Health Administration), and DOT (Department of Transportation). A confident supplier ensures that all products, especially versatile ones like sodium bicarbonate, are accompanied by the correct documentation: Certificates of Analysis (CoA) for every batch, Safety Data Sheets (SDS) compliant with OSHA's Hazard Communication Standard, and proper classification for transportation. They stay abreast of regulatory changes, such as evolving TSCA (Toxic Substances Control Act) listings, and proactively guide buyers through compliance requirements.

This regulatory expertise provides a critical shield for the buyer. It ensures that imported chemicals clear customs without delay, that they are stored and handled safely, and that their use in manufacturing does not inadvertently create liability. By serving as a regulatory guide, the supplier absorbs complexity and reduces the administrative and legal burden on the buyer, creating immense value and fostering deep dependency based on competence and trust.

Logistics, Reliability, and Risk Mitigation

The final test of a supplier's mettle is their ability to deliver the right product, in the right condition, at the right time—every time. In a post-pandemic world, American buyers have a heightened awareness of supply chain fragility. Suppliers who have invested in resilient, diversified logistics networks inspire confidence. This means having multiple sourcing options for raw materials, relationships with several reliable freight forwarders and shipping lines, and potentially strategic warehousing on U.S. soil to buffer against international shipping delays.

Risk mitigation is a proactive practice. Confident suppliers conduct scenario planning for potential disruptions—be they geopolitical, climatic, or logistical. They develop contingency plans and communicate these strategies to their buyers. For example, a supplier might secure annual contracts for container space or utilize a mix of shipping routes to avoid single points of failure. For time-sensitive products like certain grades of sodium bicarbonate used in seasonal food production or urgent environmental projects, this logistical foresight is what separates a true partner from a mere vendor.

Furthermore, packaging and handling are critical components of reliability. Industrial chemicals must arrive undamaged and uncontaminated. Suppliers must use industry-standard, robust packaging—whether 50 lb bags, 1,000 kg bulk bags, or specialized containers—that can withstand intercontinental transit. Proper labeling, including all hazard symbols and handling instructions in English, is essential for safety and regulatory compliance upon arrival in the United States. A supplier's attention to these logistical details is a direct reflection of their overall operational discipline and respect for the buyer's business.

Conclusion

Long-term buyer confidence in the American chemical market is earned through a deliberate and comprehensive commitment to excellence that extends far beyond the price per kilogram. It is built on the unwavering pillars of product consistency, as seen in reliable sodium bicarbonate specifications; radical transparency in communication and pricing; a demonstrable, certified commitment to quality and regulatory mastery; and a robust, resilient logistics operation. Suppliers like Chemtradeasia.com, who embody these practices, transition from being simple sources of material to becoming strategic assets.

For American buyers, the choice of a chemical supplier is a risk management decision. By partnering with suppliers who prioritize these trust-building practices, businesses secure more than just inventory—they gain a competitive advantage through supply chain stability, regulatory assurance, and a partner dedicated to their operational success. In the demanding landscape of American industry, this confidence is the bedrock upon which sustainable growth and innovation are built.

Leave a Comment